Presentation

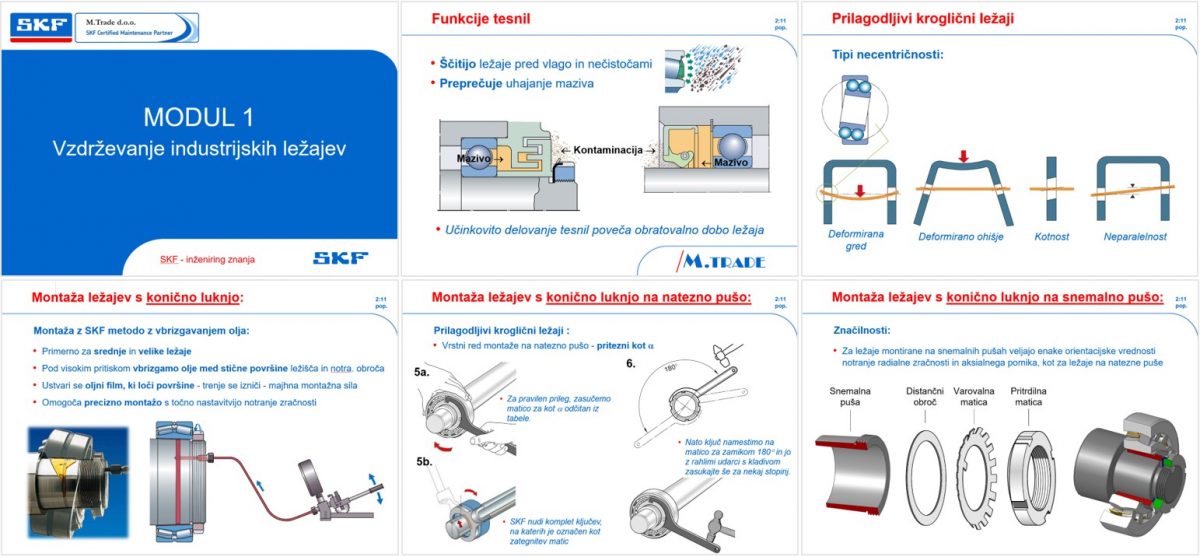

Module 1: Maintenance of industrial bearings

Participants will learn how to improve the performance of rolling bearings. This will increase the reliability of the overall machinery.

Target group:

Service technicians, maintenance technicians, engineering teams, managers and technicians for industrial plant and production where the first installation of bearings takes place. Technicians responsible for the reliability and durability of rolling bearings. Engineers working with rotating equipment, engineers in charge of the reliability of the plant, mechanics, and maintenance supervisors. Anyone with an interest in rolling bearings and the operation of industrial drives.

Module objectives:

The objectives of the module are to provide the necessary information to improve and extend the life of rolling bearings, increasing the reliability of rotating machinery.

Module Description:

The course uses a combination of practical, audio visual and theoretical basics with open discussion.

Guidance:

The training programme is led by Dr Boštjan Vaupotič, SKF certified CMP inspector. He is one of the experts in the SKF Distributor Network in Europe who has completed all SKF Distributor College courses. He is certified in SKF reliability systems for bearing lubrication, bearing maintenance, and condition monitoring of industrial drives. He is involved in bearing failure root cause analysis, in-service condition measurement of bearings and gears, machine vibration measurement and analysis, lubricant wear measurement, maintenance process optimization, lubrication system design and installation, etc.

Certificate

At the end of the course, participants take a test and receive a certificate of successful completion.

Minimum requirements:

Participants must be familiar with the basic concepts of occupational safety and possess basic knowledge and skills in the use of basic hand tools.

Training venue:

Theoretical and practical lessons are held at the premises of M.Trade d.o.o. or at your premises or by arrangement.

Duration:

The module can be fully tailored to your requirements in terms of content and time. The entire module lasts 14 school hours – 1.5 days.

Details

Content:

1. Bearing basics:

- Fundamentals of rolling bearing technology,

- storage,

- types,

- working areas,

- bearing parts,

- terminology and

- loads

- Factors affecting the performance of rolling bearings

- Bearing quality

- Operating conditions

- Installation

- Maintenance practices

2. Mounting and dismounting:

- Study of the correct procedure for assemblies and disassemblies

- Demonstration of the results of careless and improper handling, poor maintenance and lubrication

- Participation in a practical demonstration of the use of special tools for the correct assembly and disassembly of rolling bearings