Introduction

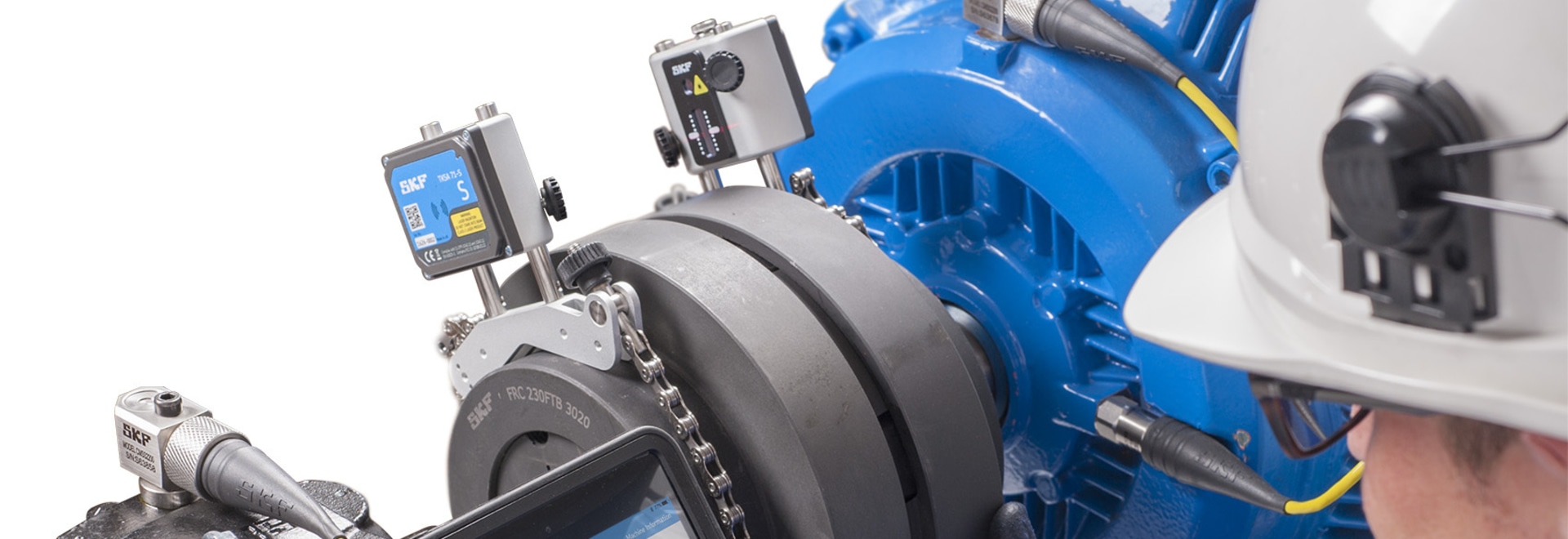

Laser alignment and centering of shafts and pulleys

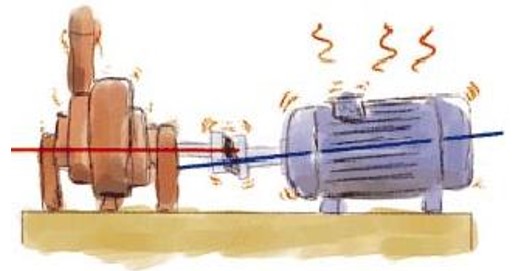

The loads caused by shaft misalignment are transmitted to all parts of the machine, causing high vibrations, leading to damage of seals, bearings, bearing housings and all machine parts.

Precision centering technology:

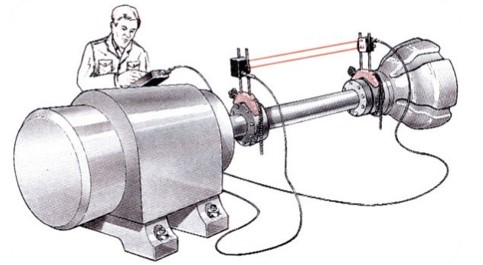

Laser alignment is a fast, extremely precise and simple process compared to conventional alignment methods. Our team of experts can carry out the most complex centering of shafts, axles and pulleys. We also carry out shaft alignment checks using laser instruments.

Details

Laser alignment and centering of shafts and pulleys

The loads caused by shaft misalignment are transmitted to all parts of the machine, causing high vibrations, leading to damage of seals, bearings, bearing housings and all machine parts.

Consequences of incorrect or poorly aligned shafts, clutches, cardans, pulleys are:

-

- increased loads

- overheating and wear

- increased wear

- increased noise

- increased vibration

As a result:

-

- reduced life of bearings, clutches, cardan joints, pulleys, belts, seals and other machine components,

- an increase in the number of unforeseen breakdowns and failures,

- the number of congestions increases inappropriate and dangerous working environment,

- increased energy consumption production efficiency is reduced maintenance costs increase,

- the overall cost of production increases significantly.

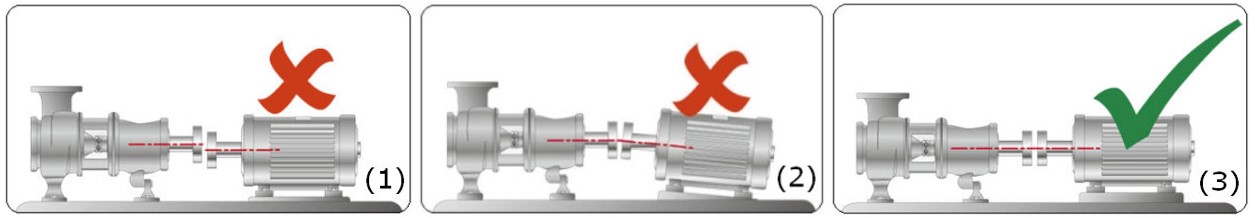

Example:

the overall cost of production increases significantly

(1) Parallel misalignment

(2) Angular misalignment

(3) Correct alignment

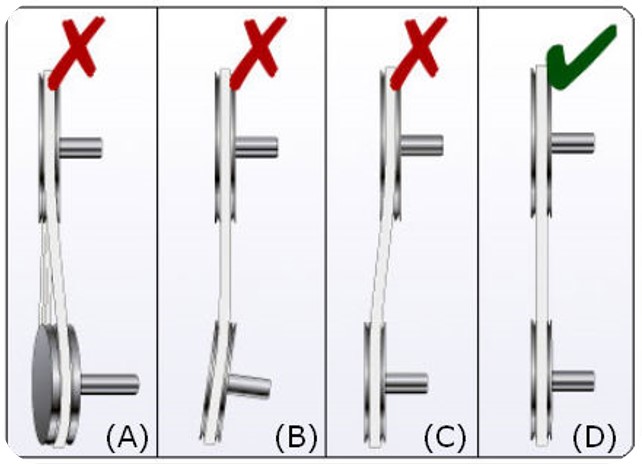

Improperly and incorrectly aligned pulleys:

(A) Vertical angular eccentricity

(B) Horizontal angular eccentricity

(C) Parallel eccentricity

(D) Right alignment

Precision centering technology:

Laser alignment is a fast, extremely precise and simple process compared to conventional alignment methods. Our team of experts can carry out the most complex centering of shafts, axles and pulleys.