Introduction

Ultrasound examinations

Measurements are made by "listening" to high-frequency sound or longitudinal waves. Ultrasound is, in fact, the mechanical vibration of an elastic medium. Its frequency range extends above the limit of human hearing, i.e. above 20 kHz. Ultrasound is also part of the noise produced by rapidly rotating machinery and devices. This allows us to “listen” to the condition of bearings, gears, whether arsing is present, etc. This method can be used to locate leaks quickly and accurately in pressurized or vacuum systems.

Ultrasound examinations include:

- Detection of leakage systems under pressure or vacuum

- Fast and accurate control of steam valves

- Spark detection in electrical appliances

- Bearing control

- Pump control

- Engine control

- Compressor control

- Control of gears, reducers…

Details

Ultrasound can be used to detect leaks in compressed air, industrial gases, and steam. The method is fast and accurate and can detect very small leaks. Most leaks are found at control valves, condensate pots, pipe joints, connectors, and preparation groups. Once the leak location has been identified they need to be eliminated. The most common leaks can be eliminated by tightening bad joints, replacing worn-out gaskets, replacing damaged or old/worn-out equipment, etc.

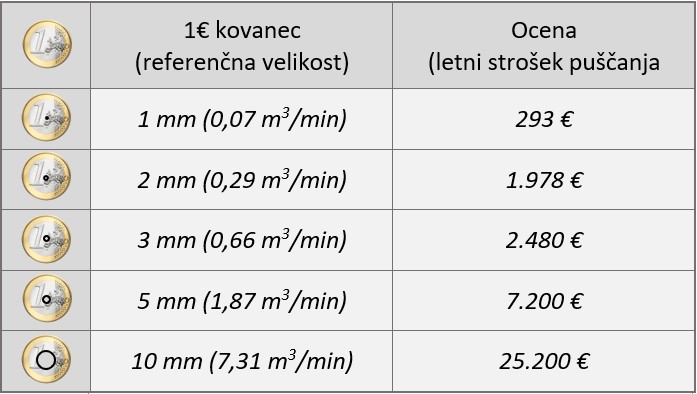

In the graph below we show the cost of an annual leak in relation to the size of the leak opening compared to a €1 coin.

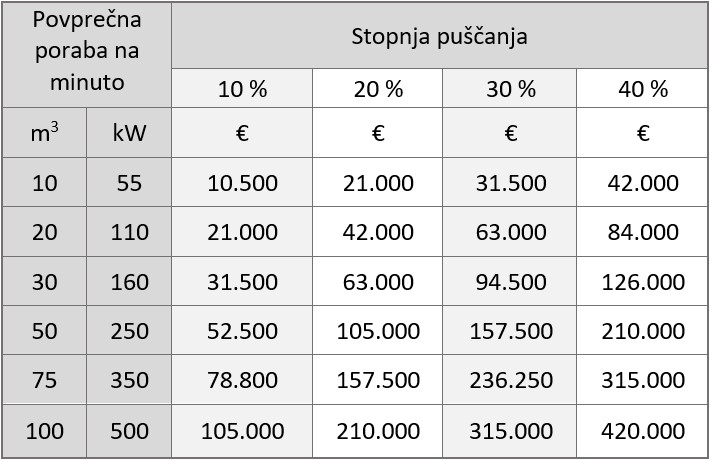

To show the cost per leakage rate, a compressed air price of 0.02€/m3 at 7 bar, 24 hours, 365 days per year is considered.

Studies show that the biggest energy savings in compressed air systems can be achieved by detecting and preventing leaks early and fixing them later. This can significantly reduce compressor operating costs and increase compressor reliability at low cost (leak detection service pays for itself in 3 to 4 months). Of course, leak detection and instantaneous repair is not sufficient measure for energy savings. It is also important to raise awareness among employees about the efficient use of compressed air. It also makes sense to designate responsible persons in the company to control the system, to close loops in departments that are currently not working. Another elegant solution is to install solenoid isolation valves with a "smart" linkage that automatically closes when the machine is stationary.

The M. Trade team will expertly and quickly measure and provide suggested solutions for your long-term savings, using systems to detect and systematically eliminate leaks of air, technical gases, and steam.