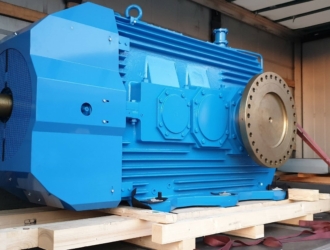

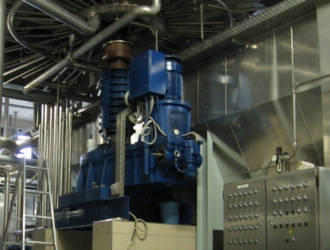

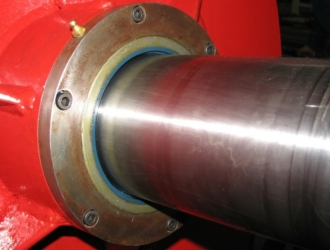

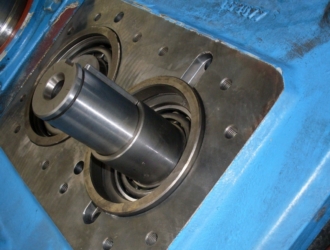

Project: Renewal of the mixer drive

The drive on the mixer was dismantled, overhauled and reinstalled. The overhaul included disassembly, cleaning and washing of all components, replacement of bearings, replacement of VS seals, alignment checks, sealing of bearing caps, measurements and diagnostics, and painting. The project was carried out on a turnkey basis.

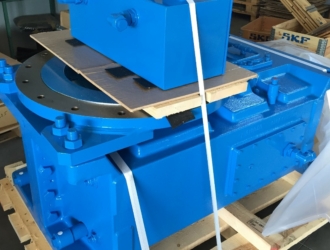

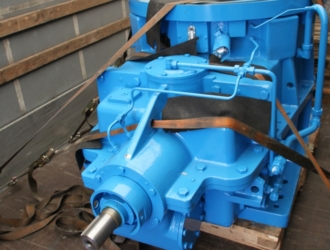

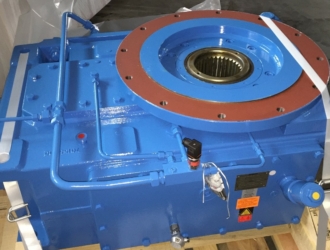

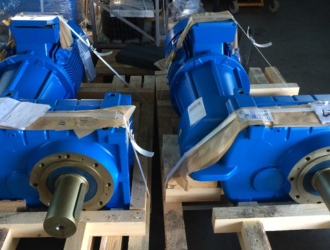

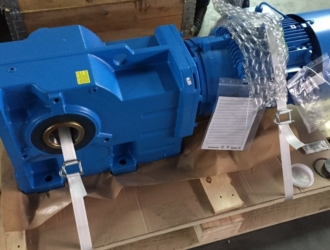

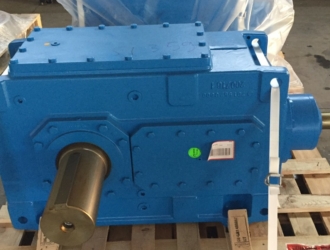

Projects: Delivery of larger gearboxes

We have successfully delivered several large gearboxes for various applications in heavy industry.

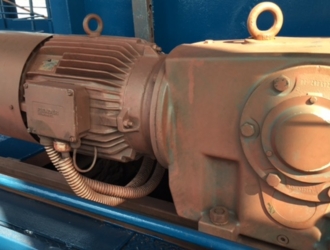

Project: Replacing a worn-out industrial fan with a new one

An old and worn-out belt-driven fan was replaced with a modern, high-capacity, economical and efficient fan. Disassembly and assembly, electrical disconnection and connection, and airflow damper control were carried out. The project was carried out on a turnkey basis.

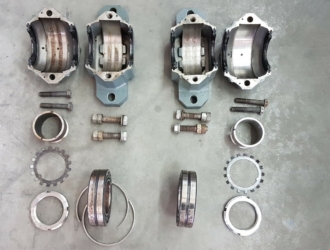

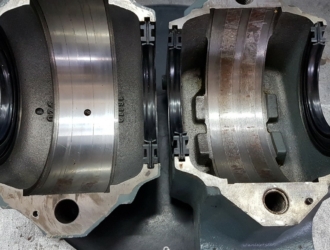

Project: Defect - analysis of the causes of bearing and machine component failures

We used various methods to visually inspect for damage to bearings, tension bushings and bearing housings and confirmed the presence of cracks in welds using non-destructive testing (NDT). An analysis of the bearing damage was carried out and the causes were identified, and remedial action was carried out on the application using the ISO fault classification standard.

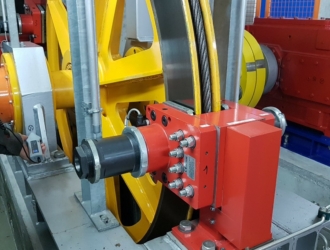

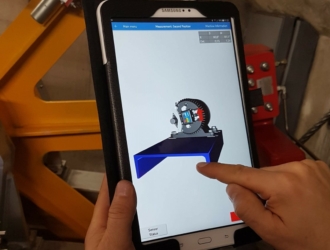

Project: Initial inspection of the drive and associated periphery of a funicular railway

As an SKF Certified Maintenance Partner and Siemens Flender Approved Partner, we carried out an initial inspection of the drive and associated periphery on a funicular drive according to the FLENDER and SKF CMP guidelines.

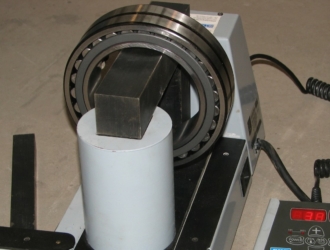

Project: Restoration of the cableway wheel

The refurbishment consisted of dismantling the worn-out bearings and axles on the cableway wheel. All bearing points were inspected and, in some places, rebuilt. The entire axle was also replaced. The bearings and axles were assembled using an induction heater, specially designed bushings, and threaded spindles.

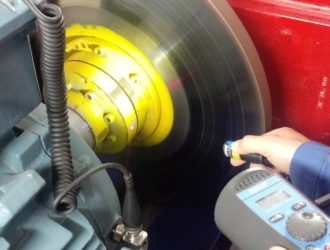

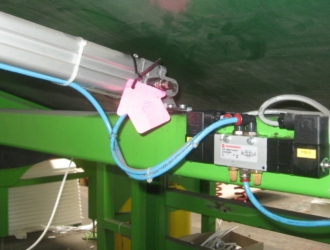

Project: Ultrasonic detection of air and technical gas leaks

We measured air and technical gas leaks in production lines and pipelines. This was followed by the elimination of the leaks detected and a follow-up check on the success of the remediation. The cost evaluation showed that the company will save approximately €20,000 per year as a result of the leak remediation.

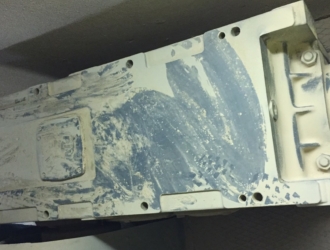

Project: Overhaul of the waste compactor

The refurbishment included a complete technical inspection of all key components, engine servicing, replacement of oil and air filters, replacement of worn hydraulic components and hoses, replacement of bearings and wheels, and painting with a high quality polyurethane paint.