Introduction

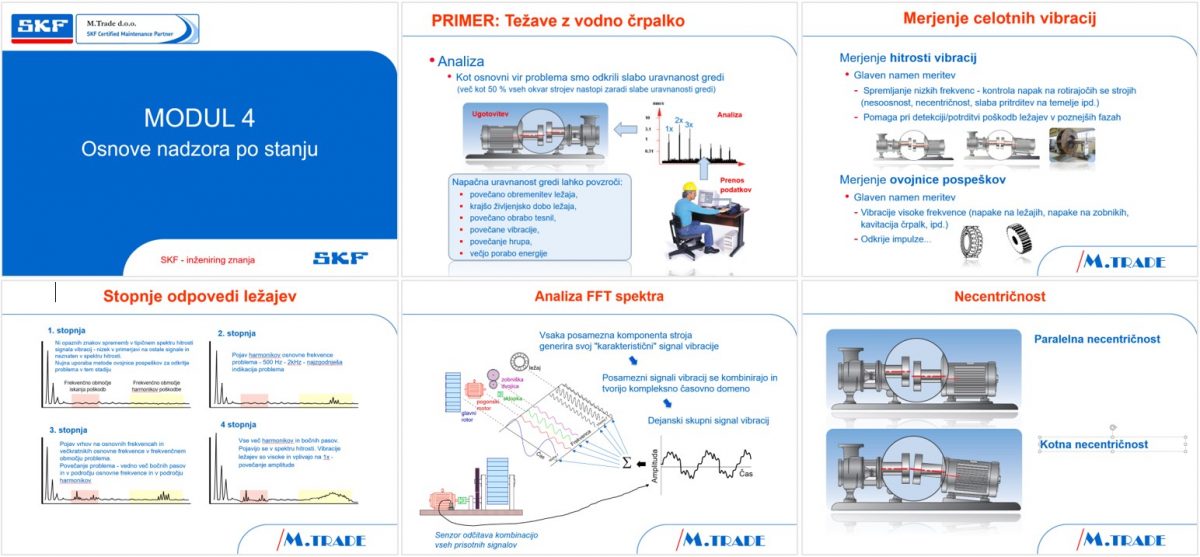

Module 4: Fundamentals of Condition-Based Control

An introduction to the training of trainees who are being trained in condition monitoring of machinery.

Target group:

Engineers, specialists and technicians who are required to be proficient in setting up and using the SKF condition monitoring system. Maintenance supervisors, condition monitoring coordinators, reliability engineers, inspectors, supervisors, specialist mechanics and anyone else who wants to learn about vibration monitoring and analysis.

Module objectives:

The objectives are to learn practical approaches to the detection and analysis of common machinery problems using vibration monitoring and analysis.

Module Description:

The module is tailored to maximise the participation of the students in the discussion. A combination of presentations, group exercises and practical measurement, preparing students to start work in the field.

Guidance:

The training programme is led by Dr Boštjan Vaupotič, SKF certified CMP inspector. He is one of the experts in the SKF Distributor Network in Europe who has completed all SKF Distributor College courses. He is certified in SKF reliability systems for bearing lubrication, bearing maintenance and condition monitoring of industrial drives. He is involved in bearing failure root cause analysis, in-service condition measurement of bearings and gears, machine vibration measurement and analysis, lubricant wear measurement, maintenance process optimization, design and installation of lubrication systems, etc.

Certificate:

At the end of the course, participants take a test and receive a certificate of successful completion.

Prerequisites:

Participants must be familiar with the basic concepts of occupational safety, and possess basic knowledge and skills in the use of basic hand tools. Participants must have computer skills.

Training venue:

Theoretical and practical training sessions are held at the premises of M.Trade d.o.o., at your premises or by arrangement.

Duration:

The module can be fully tailored to your requirements in terms of content and time. The entire module lasts 14 school hours – 1.5 days.

Details

Content:

1: The basics of vibration:

- Signal analysis over time

- Amplitude versus frequency

- Vibration – measurable characteristics

- Vibration sensors

- Measurement factors

- Dimensions and units

- Multi-parameter monitoring

- Resonance

- Detection in relation to analysis

2. Vibration measurement items:

- Physical and database assumptions

- Machine selection

- Sensor location and mounting methods

- Cable routing

- Fmax placement

3. Alarm methods and setting alarm limits:

- ISO guidelines

- Assessment of the severity of total vibration

- Spectrum envelopment and explanation

- Phase alarms

- Exception criteria

4. Spectral and phase analysis:

- Spectral analysis techniques and pattern recognition

- Sidebands

- Harmonics

- Waterfall extraction

- Understanding phase

5. Vibration signal processing methods:

- Enveloping

- SEE Technology (Spectral Emitted Energy)

- HFD (High Frequency Detection)

6. Analysis of typical machine problems:

- Debalans in necentričost

- Zvita gred

- Mehanska zračnost

- “Ukleščen” ležaj

7. Monitoring rolling bearings:

- Disbalance and off-centrality

- Cranked shaft

- Mechanical clearance

- “Angular contact” bearing

8. Vibro-diagnostic tables:

- ISO 2372 vibrodiagnostics table